NEW – NEW – NEW

AR-4U service partner

We use CAD data that was either created through Reverse Engineering or come directly from you to use in Augmented Reality applications. This now makes it possible to turn and transform any product into a 3D model and enable fast-paced AR experiences. Click here to learn more.

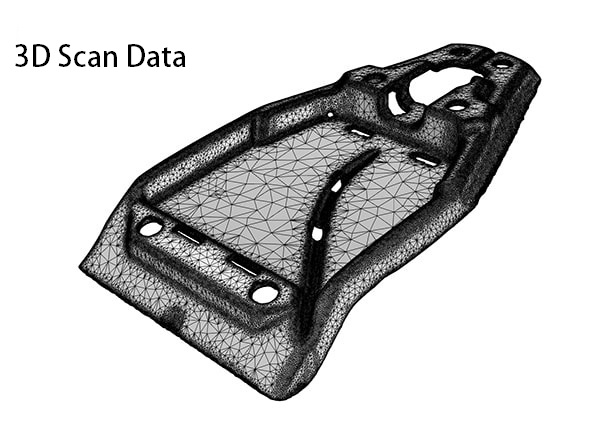

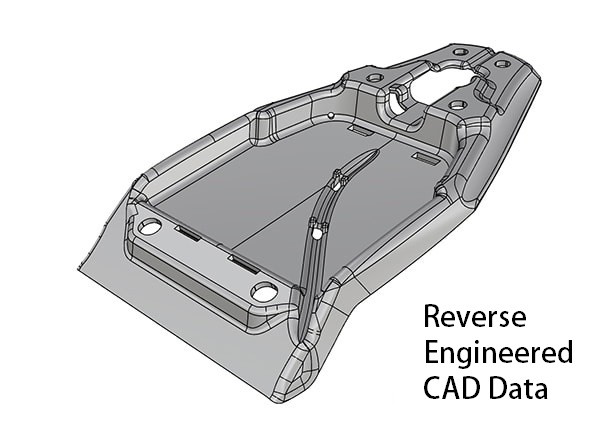

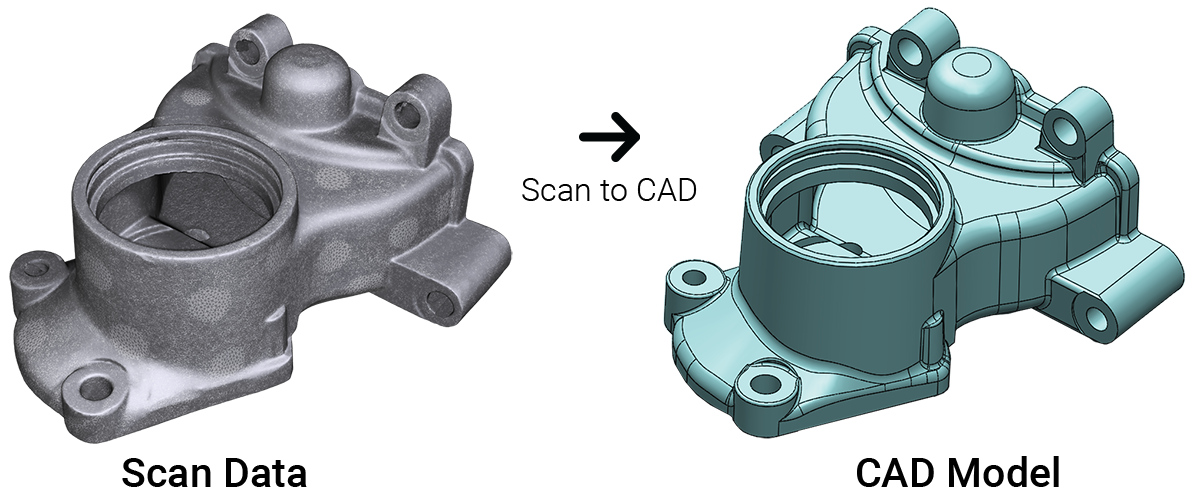

REVERSE ENGINEERING PROCESS CONVERT YOUR 3D SCAN TO CAD DATA

Solutions for large quantities of scan data.

Fast processing, discounts based on quantities, top quality.

3D REVERSE ENGINEERING SERVICES FOR CAD

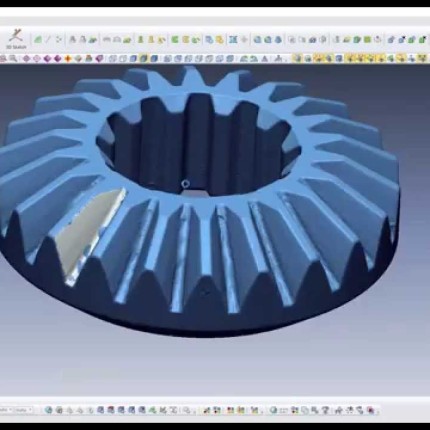

Reverse Engineering in Parametric Data

Create CAD Data with Parametric History

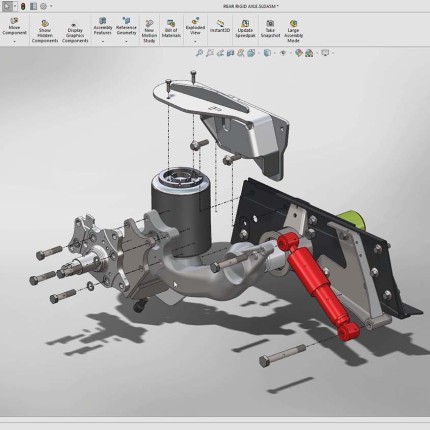

SOLIDWORKS

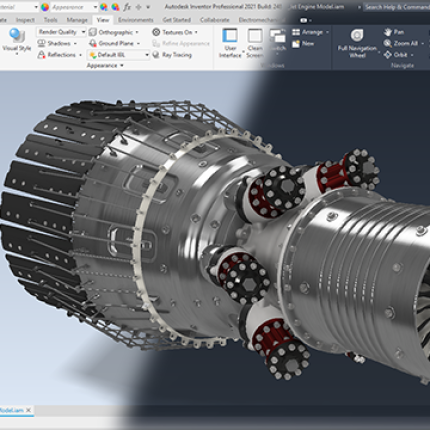

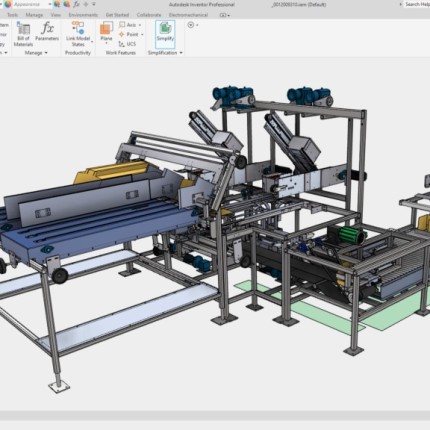

AUTODESK

INVENTOR

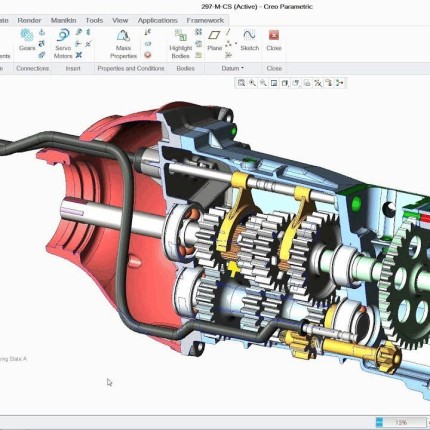

CREO

CATIA

For reading data directly, we offer parametric data records. We offer native CAD Data in:

- Reverse Engineering in Solidworks

- Reverse Engineering in Autodesk

- Reverse Engineering in Inventor

- Reverse Engineering in CREO

- Reverse Engineering in Catia

CAD Data for these Softwares are always created with parametric history. To change single geometric elements of the scanned object, we create a CAD file according to your demand in the data format you need.

For example Solidworks - The geometry of the scan-data is directly recreated in Solidworks. The result is a Solidworks file, which can be opened and edited with parametric History in Solidworks.

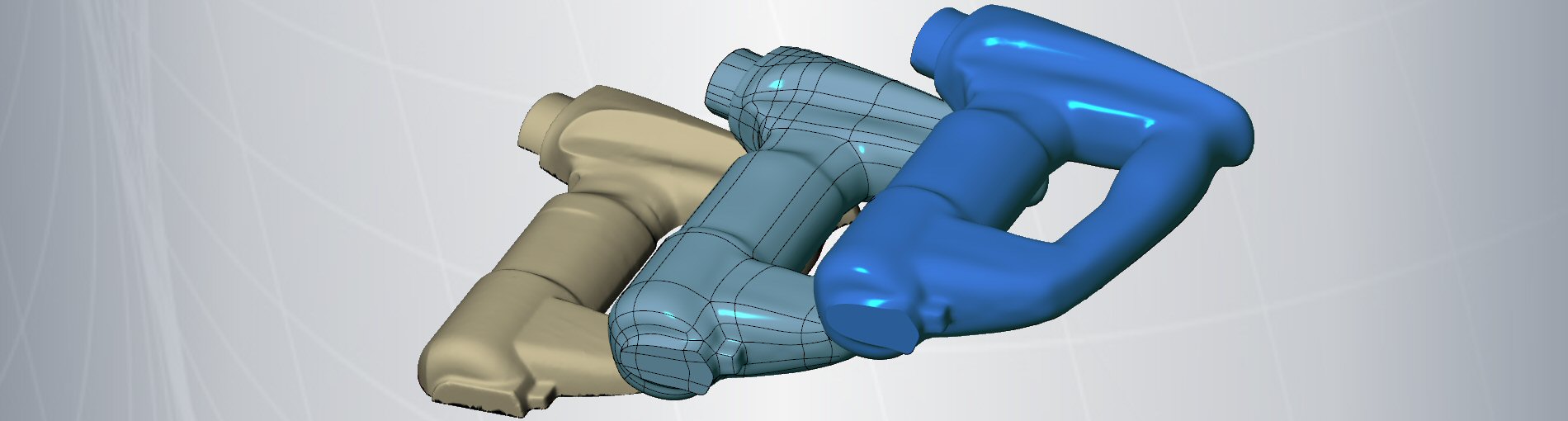

Reverse Engineering in Volume-Data

Create CAD files out of Scan Data

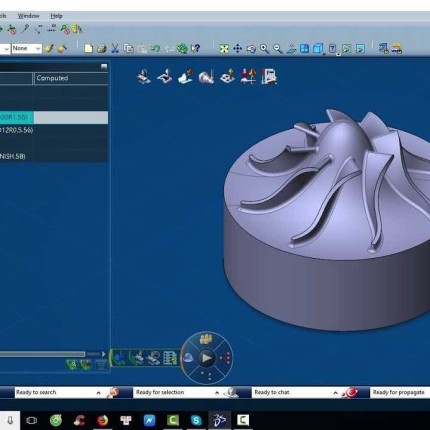

DESIGN X

SIEMENS NX

For processing as a complete element in a sequel construction, for measurements or e.g for calculations of volumes, cheaper and faster created Volume-Data is sufficient. We create Volume-Data with Siemens NX or Design X.

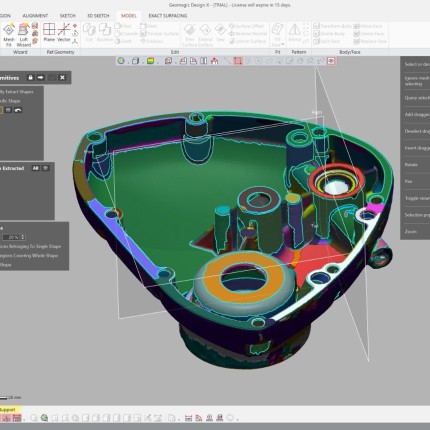

- Design X (Geomagic) - The scan-data will be read and converted into surfaces in a mix of manual und semi-automated process.

- SiemensNX - The scan-data will converted into surfaces manually after reading the data.

The resulting data is available in STEP format as a *.stp file.

REVERSE-ENGINEERING SERVICE

Based on your requirements on the reverse-engineering we choose the right software to create parametric data or volume data. The engineer decides the right way for reconstructing the scan data into CAD data based on his experience.

Advantages of 3D Digitalization for the industry:

- CAD Data with Reverse Engineering for form- and tool manufacturing

- Repair and extension of existing products

- Easy communication with CAD data sets and more

Reverse Engineering Consulting

Our team, currently including about 30 construction-engineers experienced with almost every reverse-engineering software in use, will give you the right answer to your questions. We will be happy to advise you.

We analyse the 3D scan and we notice the elements which were planned in the real component. Afterwards the single dots in this area get converted into a surface. This process is called Reverse-Engineering. The new CAD file can be created with parametric history and it can be used for further constructions instantly.

The Reverse Engineering makes it possible to digitalise highly complex components for every CAD System in a very short time. We offer data which meet the professional industrial requirements and is created with striking price-performance ratio.

Reverse Engineering Quality

We create high quality by layering surfaces (resulting from the single scanned dots) on the point cloud.

Due to this reverse engineering, we are able to deliver CAD Data which meets the professional requirements in the industry.

PORTFOLIO

Automotive industry, casting industry or amusement, we have been working in various fields for years using 3d scan data.

We have the experience to know exactly what types of reverse engineering you need. As examples, we present four projects on Reverse Engineering below:

CONTACT US & ORDER SAMPLES

If you submit your contact information here, you will get a link to download the Sample Reverse Engineered data. Take your time to evaluate the quality of our Reverse Engineering or use the 'Message' field to submit a request to our team of experts.

PARTNERS

Our cooperation partners...