3D DIGITALIZATION - CONVERT 3D SCAN INTO CAD DATA

3D Digitalization: Create tools with high precision.

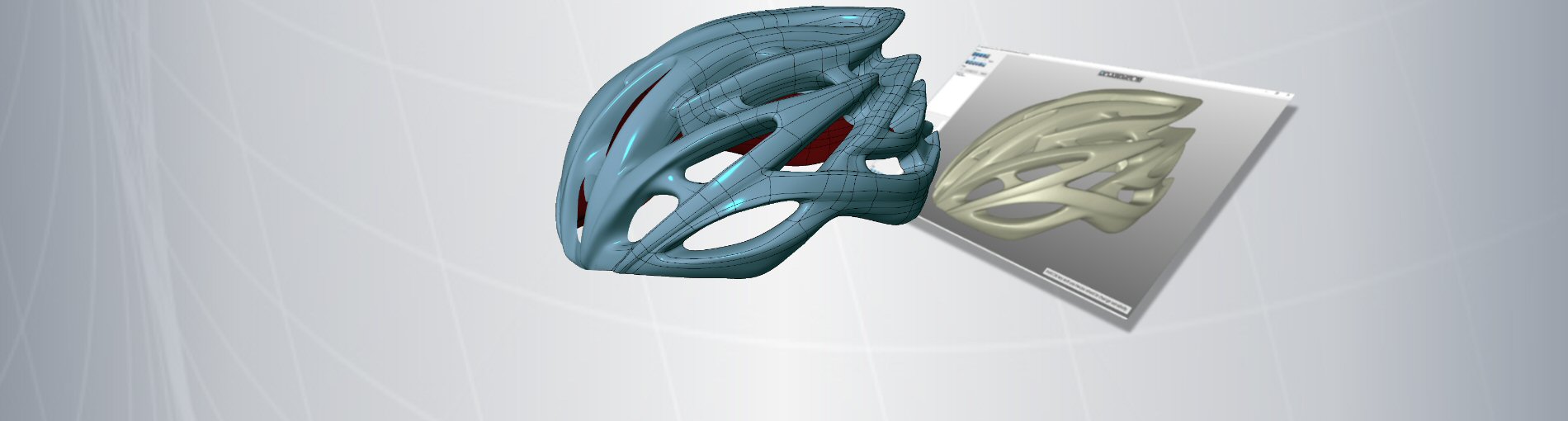

3D Digitalization: Generate optimal CAD data from the model with 3D Scan.

CAD DATA FROM THE WORKPIECE THROUGH 3D DIGITALIZATION

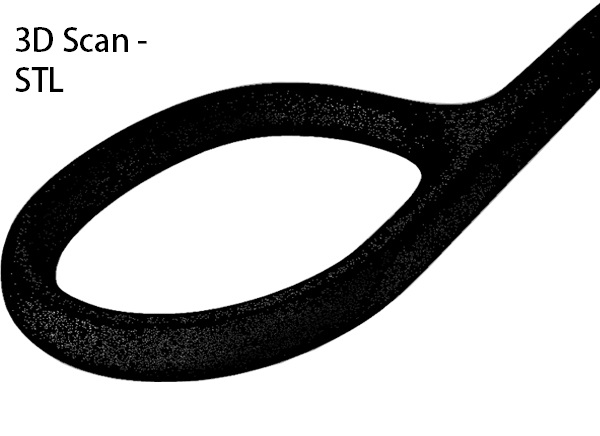

3D scanning of the workpiece

The first step in 3D digitalization is the 3D scanning of your workpiece. The professional and inexpensive 3D digitalization of workpieces is now possible for everyone with little effort and a 3D scanner. You create your 3D scan data on site and benefit from very fast running times, low costs and easy communication.

Of course, we can also provide you with a 3D scan of your parts.

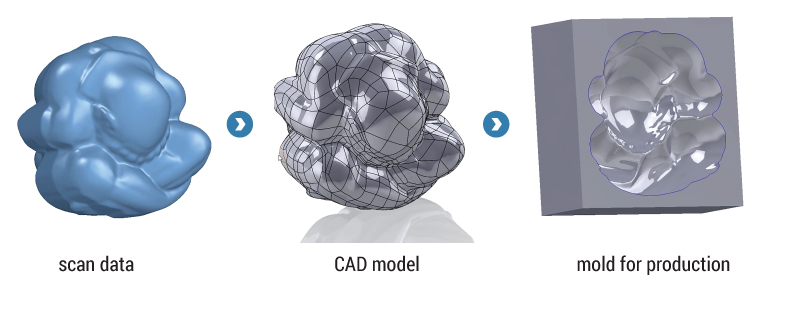

The processing of the 3D scan data in CAD data

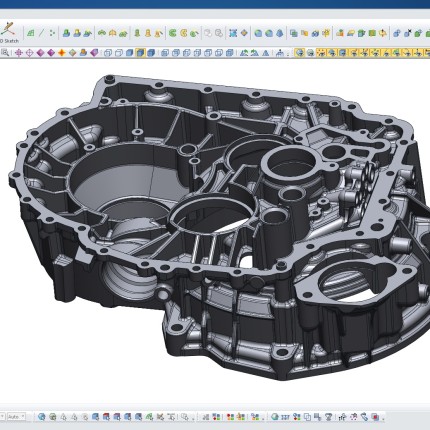

The second step in the 3D digitalization is the conversion of the point cloud generated in the 3D scan into CAD / CAM capable data. The preparation of your scanned STL data requires years of experience from professional engineers in the reconstruction in CAD.

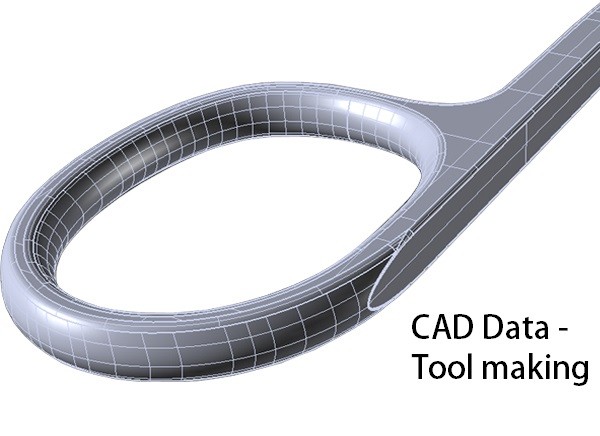

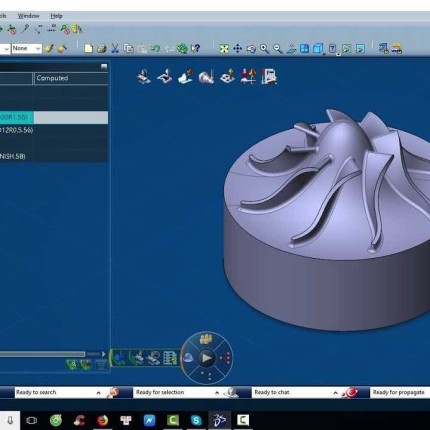

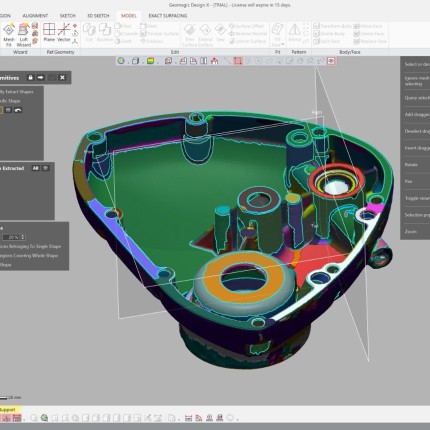

In 3D digitalization, the specialist engineer recognizes the logic of the workpiece based on the scan points and replaces these points with CAD-capable surfaces. We process the scanned data record with this reverse engineering to match your desired CAD software.

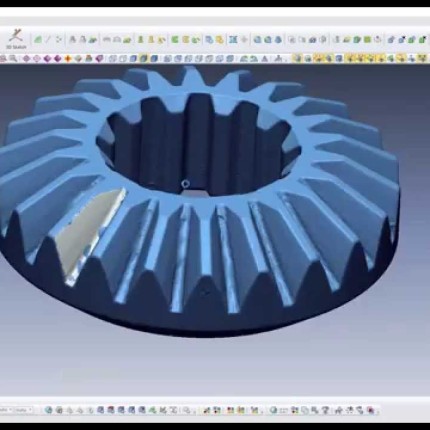

Based on the scan data we construct a CAD / CAM capable solid model. You can choose between a parametrically constructed design, a surface reconstruction in a STEP / IGES model or a combination of both.

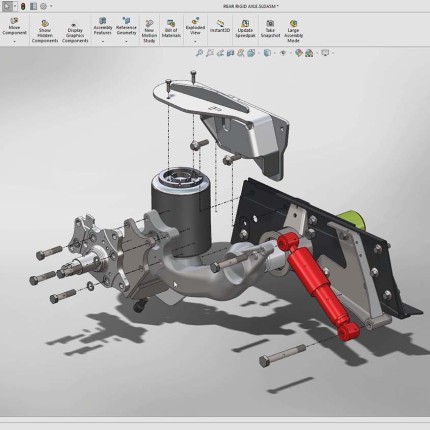

Parametric regular geometries and free-form constructed surfaces are created natively in Solidworks, Catia or CREO. For STEP or IGES models we use SiemensNX or DesignX (Geomagic) - further sample data can be found in the download link below.

Tolerances of 3 - 5 /100 mm are possible with recent scanning systems. The manual and logical reverse-engineering of scan data guarantees that deviations out of the scan file are removed in the new dataset. A 90° scaned angle will manually be replaced with a 90° solid angel. Any automated software process would completely copy all tolerances out of the scan instaed of providing you with clean surfaces.

Your tool can be created immediately with the finished data.

3D Digitalization: Reverse Engineering Procedure

3D Digitalization in Parametric Data

Create CAD Data with Parametric History

SOLIDWORKS

1. Solidworks – Reverse-Engineering in native Solidworks data with Construction history

AUTODESK

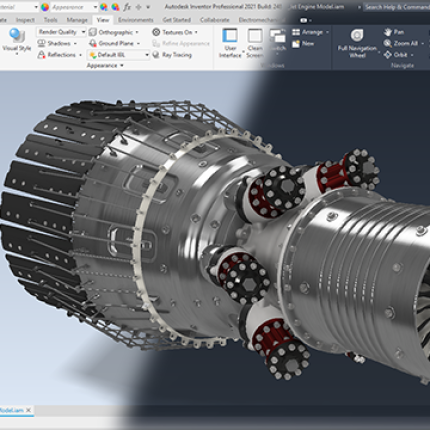

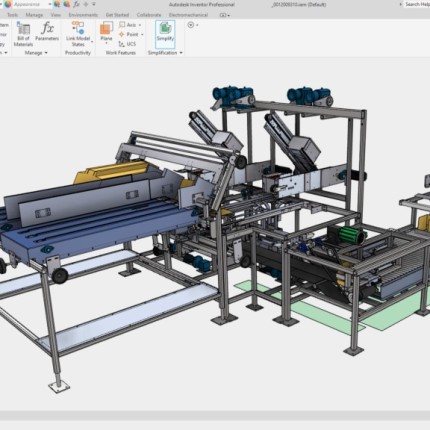

2. Autodesk – Reverse-Engineering in native Autodesk data with Construction history

CREO

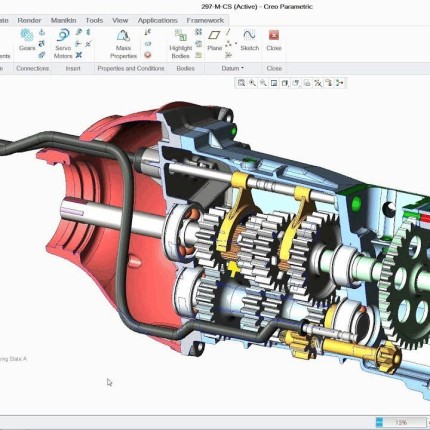

3. CREO – Reverse-Engineering in native CREO data with Construction history

INVENTOR

4. Inventor – Reverse-Engineering in native Inventor data with Construction history

CATIA

5. CATIA V6 – Reverse-Engineering in native CATIA V6 data with Construction history

3D Digitalization in Volume-Data

Create CAD files out of Scan Data

DESIGN X

1. DesignX – Reverse-Engineering in STEP

DESIGN X

2. DesignX – Reverse-Engineering in IGES

SIEMENS NX

3. SiemensNX – Reverse-Engineering in STEP

SIEMENS NX

4. SiemensNX – Reverse-Engineering in IGES

OUR 3D DIGITALIZATION SERVICE

3D Digitalization - consulting on 3D technologies

Our TEAM, of currently approx. 30 engineers, processes 3D scan data for import into your CAD software. As a service provider for reverse engineering, we have a network of partners and colleagues who offer almost every service in the 3D area. We assist in creating a 3D scan, data preparation and we can help with 3D printing. For your toolmaking processes, the scanning of a model and converting it into CAD / CAM dataset can provide a significant time and cost advantage. - We are happy to help.

Tools - quality and benefits through 3D Digitalization

Increase your product quality by creating accurate 3D scans. Your production benefits from optimally prepared data for the tool design. The quick replacement of your component offers new possibilities in communication.

3D DIGITALIZATION IN TOOL MAKING - DO YOU HAVE A QUESTION?

If you submit your contact information here, you will get a link to download the Sample Reverse Engineered data. Take your time to evaluate the quality of our Reverse Engineering or use the 'Message' field to submit a request or question to our team of experts.

PARTNERS

Our cooperation partners...